Bedding The Turk Action - Part 1 - Making The

Pillar

"Bedding"

an action is a way of providing a zero clearance fit between the action and the

stock and a method of insuring that the effects of recoil are properly resisted

by the stock. A skilled craftsman, with lots of time, and a new stock, can

carve the stock to perfectly fit the action. I cannot do that and, if I could,

usually I don't have a virgin piece of wood to work with. So, if you are like

me, you could "Glass Bed" the action to the stock. "Glass

Bedding" is a process of filling the voids between the wood and the action

with some sort of epoxy resin. In some cases, wood is removed so as to loosen

the action in the stock, so that when resin is used it is some thicker.

A rifle using a Mauser action can benefit, accuracy wise, from a good glass

bedding job, and the Turk is no exception.

When I bed a Mauser action (like a Turk) in an existing stock, I start

with the rear pillar. The pillar is nothing more than a piece of metal spanning

the distance from the rear tang of the receiver to the rear tang of the lower

strap or trigger guard. This piece has a hole thru which the rear action screw

passes. A piece of metal with a hole thru it sounds like a pipe, and that is

what we will use. Pillars in both stainless steel and aluminum are available

from Brownells, but it is easier and just as good (and

cheaper) to make your own.

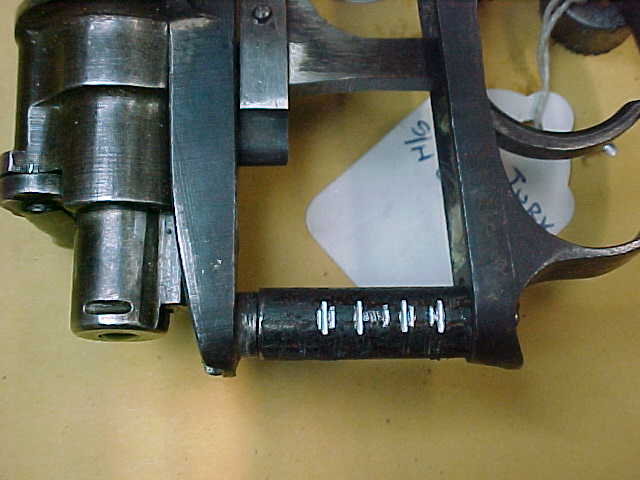

The picture above shows the

rear of a K.KALE action being measured to determine

the length of the pillar. The front action screw is snug,

the rear is loose. The magazine well is firmly against the receiver rails. The

dial indicator is reading 1.192 inches. To the left are two pieces of "1/8

inch" pipe. This pipe measures a little less than 1/2 inch on the outside

and about 1/4 inch inside. The correct trade name is 1/8 inch IPS, Schedule 40,

or Standard Weight. Purchase a 4,5 or 6 inch steel

nipple at the hardware outlet. (About $1.00) It will come in "black

iron" or "Galvanized", with "black" being preferred,

Galvanized OK. Measure your action, with the long screw a little loose, cut off

the threads from one end of the nipple and cut a piece of the pipe (nipple) a

little longer than the desired measurement. A hand hacksaw works fine. If you

want to know what to do with the rest of the nipple - Check this out.

Drill (ream ?)

thru the piece you cut off with a 5/16 drill. Holding the piece in a vise is

best, but a pair of vise grips or Channel Lock pliers with the pipe held

against a block of wood works well.

After drilling the inside,

grind or file the outside, keeping the faces flat and parallel until the piece

is just the right length. In this case, 1.192 inches. (Your action will be

different !!!)

This is the finished pillar,

ready to install in the stock. With your hacksaw or Dremel

wheel, cut some "gashes" around the outside, BUT DO NOT CUT THRU THE

WHOLE WAY. These gashes will help the epoxy get a grip on the pillar.