IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGETHIS WILL TAKE YOU TO

PAGE ONE OF THIS SERIESStover CT-3 - Page2

Just another view of how bad it was.

Once the piston was out, it soaked in a secret solution for about 3 weeks, and the ends of the piston ring popped free, however, I managed to break them in the area that had laid full of water. So, new rings were ordered from Hit n' Miss.

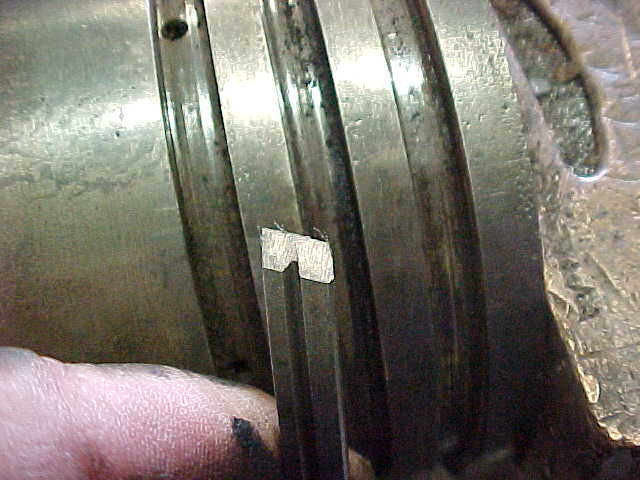

One of the rings was ground to a sharp knife-edge and the ring grooves were scraped using this tool. The pointed edge got into the inner corner, and when the groove was cleaned all the way round, the piston was swapped end-for-end, and the opposite corner was cleaned

Before the tool was pointed, a flat edge was used to clean the bulk of the crud out, but see the stuff in the inside corners?

I forgot to mention, that is I forgot until I went to blast it, that the exhaust rocker was broken and the end that meets with the pushrod was lost. I fabricated a new rocker from a steel bar and used cam-follower bearings as "tappets".

I didn't remove the flywheels from the crank for sand blasting, but covered the crank with duct tape. BIG MISTAKE - cover the crank with masking or electrical tape and THEN duct tape. The duct tape resisted blasting very well but left a very messy clean-up.