Jeweling or Engine Turning the Bolt

After you have bent, welded or

otherwise relocated the bolt handle, or maybe if you haven't, a nice touch is

to Engine Turn the bolt. You know, those little swirls found on fancy custom

rifles. Here I will show how this is done and how to make a suitable (cheap)

jig to hold the bolt.

Brownells sells jeweling jigs, one by B-Square

for $45, and one by Wilcox for $190. The one shown here costs about $5.

In addition to the jig, you

will need a drill press, jeweling brushes and abrasive compound.

In the plastic bag are 3 Brownells jeweling brushes, upper right is a can

of 400 grit abrasive compound in oil, then a piece of surgical tubing, a single

brush, and a brush covered with tubing. You can use 120 grit compound or valve

grinding compound. The surgical tubing is optional, I

find it holds the brush together.

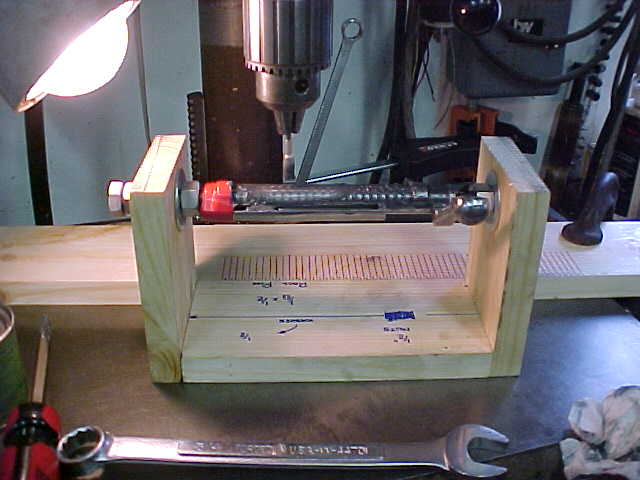

Try to ignore the stuff in the

background J . Here is a bolt, in a jig, centered under a brush mounted

in the press. The bolt has been smeared with grinding compound and when the

brush is brought to bear on the bolt, little swirls are made. The extractor is

left on the bolt, positioned as it would be when the bolt is closed, and held

in place with the red electrical tape. If you have a jig, follow the

instructions that came with it.

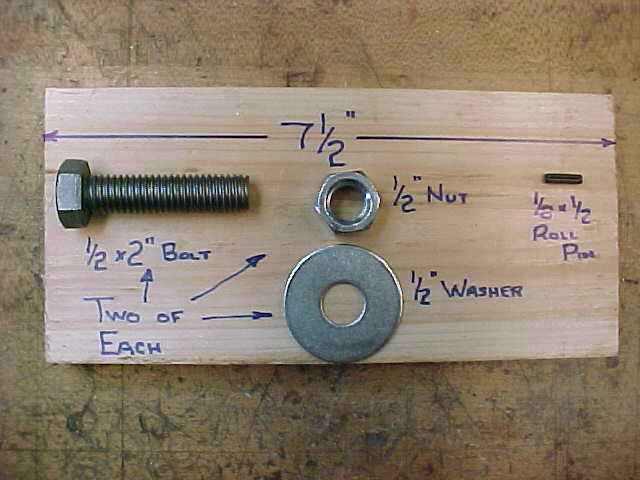

If you want to build a jig,

IGNORE THE "TWO OF

EACH". You will need 2 ea. 1/2 x 2-inch bolts, 3ea. 1/2-inch washers, 3ea.

1/2-inch nuts and one 1/8-inch x 1/2-inch long roll pin and some wood. One

piece of wood, shown above is 7 1/2-inches long, cut from a 1 x 4.

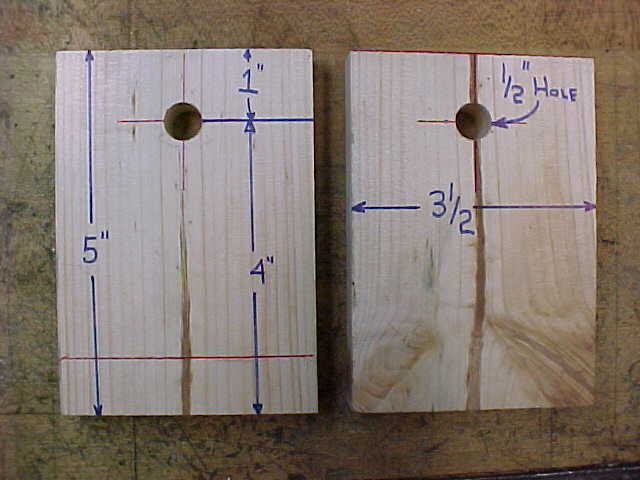

Then two more pieces 5-inches

long, with 1/2-inch holes, centered, 1-inch from the end.

Steve Wagner

Bellwood PA