IF YOU GOT HERE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO THE WAGNER HOME

Anodizing the AR15/M16 Bolt Stop Extension

Or

Small-Lot Anodizing

Aluminum is soft, and seems hard to paint. Anodizing can be the cure for both .

The surface of a piece of aluminum has a layer of aluminum oxide about one molecule thick, and if you scrape through this layer and expose some virgin metal, a layer of oxide forms in a matter of seconds, using oxygen from the air. Now, Aluminum Oxide is VERY hard, grinding wheels and sharpening stones are made from it. If the layer could be made thicker, then the surface of a piece of aluminum would be "case-hardened" (not really but sort of). The process that "thickens" the oxide layer is called "ANODIZING". AND, if the anodizing is done at 75 degrees F. or less, the Aluminum Oxide layer will have microscopic pores in its' surface. These pores can be filled with dye, and if then heated to 212 degrees F. the pores will close-up, sealing the dye in place. Pretty neat, Eh, harden and color in one nice little process!

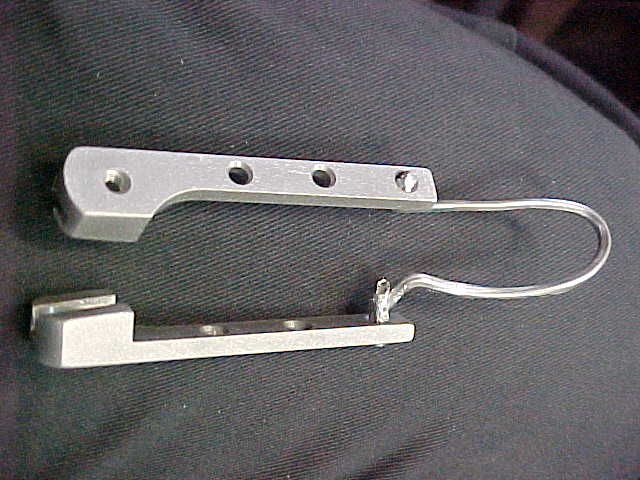

First, an electrical connection is made to the piece of aluminum to be anodized. I used short pieces of aluminum wire salvaged from Service Entrance cable. The ends are doubled over and "threaded into a tapped hole. The wire is very soft and accepts the threads without damage to the threaded hole.

Ý

Ý Ý Here are two Bolt Stop Extensions, one on each end of a short aluminum wire.

And here is the whole thing. Ý Ý Ý

Ý

Ý Ý The two pieces (times two - shown above) are hung over a wooden stick and submerged into a mixture of battery acid and water. The acid can be had from an Auto Parts store, the "motor cycle battery fill kit" was $5. The aid is mixed with an equal amount of water. The acid/water mix is in a glass or plastic container and an aluminum bar is also submerged into the mixture.

Ý

Ý Ý The positive lead of a battery or power supply (green and yellow wires above) is connected to the work, and the negative lead (black wire above) is connected to the aluminum bar. As the anodizing proceeds, the temperature of the acid will rise. In order to cool the acid, the whole thing is submersed in cold water. I am using a chiller, but ice cubes work well. The extensions have a surface area of about 3 sq. inches, and require about 1 amp for maybe 75 minutes for proper anodizing.

Ý

Ý Ý I used a power supply, but a battery charger will work as well.