IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGEThis will take you to the Reloading Index

Steve's Rifle Cartridge Reloading

These are the techniques and equipment that

I use to produce reloaded cartridges for bolt and semi-automatic rifles. Other techniques and equipment may be: better/worse, cheaper/costlier, safer/more dangerous or whatever. Read this stuff and use it or not, at your own risk!Trimming Cases to Length

Every time a case is fired it grows in length a tiny bit. This is due to cold flow of the brass into the only place it can go and to working of the brass due to "looseness" of the case in the chamber. The cold flow is related to brass tensile strength and the internal pressure when fired, with hotter loads growing more. Keeping the ammo to the minimum headspace and/or limiting sizing to the neck area only can minimize the growth due to looseness.

The reason for trimming this growth, aside from some rather esoteric neck tension issues, it that if the end of the case hits the "step" at the end of the chamber when chambered, the case mouth will be crimped into the bullet, or the round will not allow the bolt to close. The unintentional crimping can cause dangerously high chamber pressure. The failure of the bolt to close is annoying, rather than dangerous, and is many times interpreted as a headspace issue.

Case length is measured from the case base to the end of the mouth and should be done AFTER RESIZING! The correct length can be found the most reloading manuals.

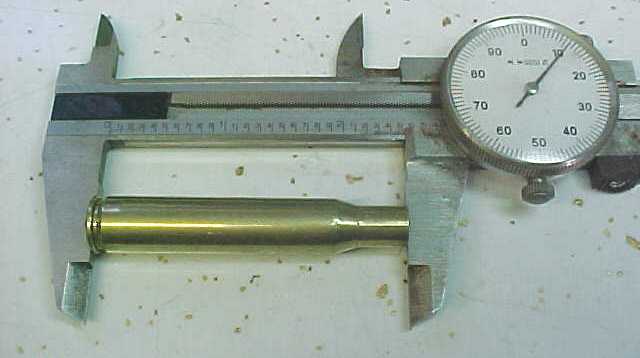

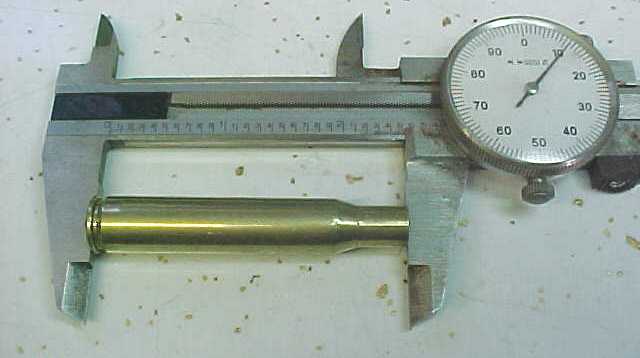

It can be measured using a $10 dial caliper,

or by using a Wilson case length gauge. (This case is too long, the correct length would fall between the high and low flats on the gauge end.)

This is a Forester hand trimmer. The case head is held in a collet above my thumb.

Above is a close-up of the collet, empty. The steps in the collet make it universal; it will accept almost any round.

Here to collet is holding a 30-06-size case.

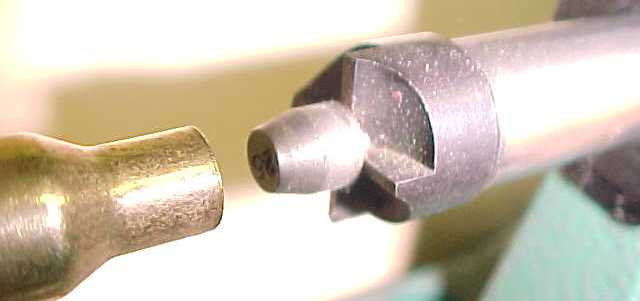

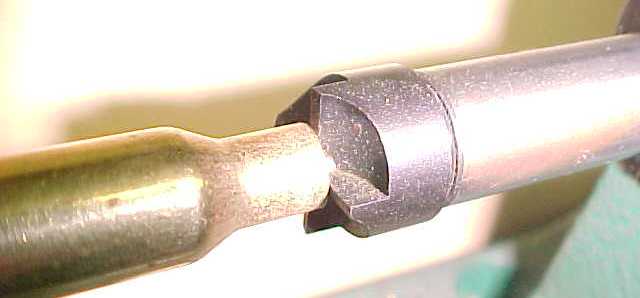

This is the business end, the interchangeable pilot that fits into the case neck, and the cutters that trim the end to length. A stop collar on the rotating spindle is set to limit the cutting action when the correct case length is reached.

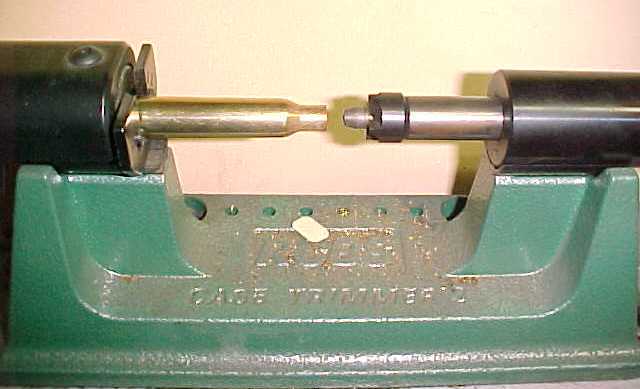

This is an RCBS motorized trimmer, with the motor located in the squarish box to the right.

The case is held in a quick-release holder to the left.

This unit has a pilot/cutter assembly.

Here the pilot is inside the neck and the cutters are ready to work.

AFTER TRIMMING, THE INSIDE (AND MAYBE THE OUTSIDE) OF THE NECK SHOULD BE CHAMFERD!

Some Trimmer Prices for Comparison

These are wholesale prices effective 3-7-03

RCBS Hand Powered Trimmer - $61.50

RCBS Powered Trimmer - $159.90

Hornady Hand Powerd Trimmer $51.90

This will take you to the Reloading Index