IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGEThis will take you to the Reloading Index

Steve's Rifle Cartridge Reloading

These are the techniques and equipment that

I use to produce reloaded cartridges for bolt and semi-automatic rifles. Other techniques and equipment may be: better/worse, cheaper/costlier, safer/more dangerous or whatever. Read this stuff and use it or not, at your own risk!Priming

Resized cases need to have primers installed. If not the powder just runs out of the hole. WHEN PRIMING ANY CASE, KEEP YOUR HANDS AWAY FROM THE CASE MOUTH AND KEEP THE CASE MOUTH POINTING AWAY FROM YOUR EYES.

I use an RCBS bench priming tool. This tool feeds primers from a metal tube having a capacity of 100 primers.

The tube is filled by picking up the primers in the plastic "jaws", from a tray. For a link to see how these primers got into the tray, here's a link.

The primers are automatically transferred from the tube to a movable anvil passing through a shell holder. A case is placed into the shell holder and the primer is forced up into the primer pocket. The bench priming tool allows me to "feel" the primer as it enters and seats itself into the primer pocket of the case. Any cases that "feel odd" during the priming process are set aside and either discarded or used for practice/testing rounds.

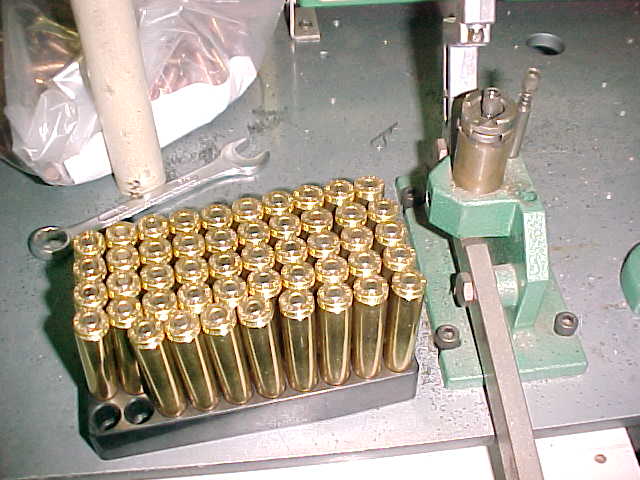

The primed cases are held upside down in a tray. These trays come from the range trash cans J . Keeping the cases upside down prevents stray material from falling into the cases. It also allows the primers to be inspected, both visually and by running my fingers over the primers. This to check for primers that may not be fully seated. In order to have uniform ignition when fired, it is important to uniformly seat the primer, and if not seated fully, slam-fires may occur.

Another popular seating tool is the hand held design. These are offered by RCBS and Lee and maybe others. Both RCBS and Lee use a removable shell holder the capture the case while being primed. The Lee tool uses special holders, not interchangeable with the reloading press shell holders. The RCBS hand held unit uses the same holders as the reloading press, but only those holders manufactured by RCBS will fit. This "dirty trick" is because of the design of the RCBS holders.

At the left is a Lyman holder and to the right is an RCBS holder. The RCBS unit is flared on the bottom. The lack of this flair prevents the Lyman unit from being installed in the RCBS priming tool. A little work with a Dremel tool will fix the problem.

This will take you to the Reloading Index