IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGEThis will take you to the Reloading Index

Steve's Rifle Cartridge Reloading

These are the techniques and equipment that

I use to produce reloaded cartridges for bolt and semi-automatic rifles. Other techniques and equipment may be: better/worse, cheaper/costlier, safer/more dangerous or whatever. Read this stuff and use it or not, at your own risk!Dispensing Powder

Now that you have some polished, sized, trimmed and primed cases, it's time to out some powder inside. There are a few different ways of doing this; all of them require a scale.

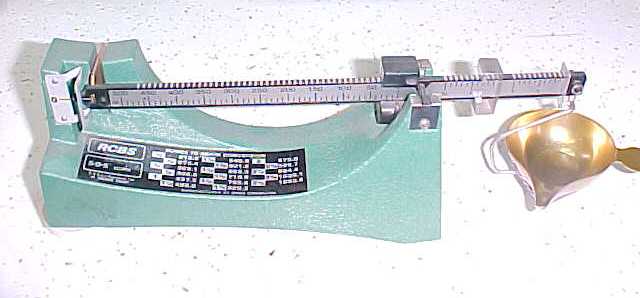

The most common reloading scale is the single beam balance scale, so called because it has a single beam with a pivot near one end and a series of sliding weights that can be so positioned so as to balance the mass being weighed. As a testimonial to this type of scale, it is VERY popular in the drug trade, it keeps the druggies honest, where as the electronic scale can be inaccurate (by intention or otherwise), gravity is pretty consistent. The beam is supported by two hardened steel "knife-edges" resting on two glass or jewel bearing surfaces. These edges and blocks are very fragile and when the scale is moved, the beam should be lifted from the glass blocks, or at least held with your thumb so as to prevent bouncing. When not in use the scale should be covered with a piece of cloth and the beam should NOT be balanced,

Although relatively cheap, this one was manufactured by OHAUS, a very respected name in the scale world.

The cheapest, and some say best, way to come up with a weighed batch of powder, is the trickler. As seen above, a trickler is a vertical cylinder, closed with a weight at one end, with a transverse tube passing through the body about mid-way up. The big tube is filled with powder and the transverse tube is rotated by hand (sometimes a motor). Powder enters the rotating tube through a hole inside the powder reservoir and exits out one end. The powder "trickles" out, thus the name, at a rate that is easy to control.

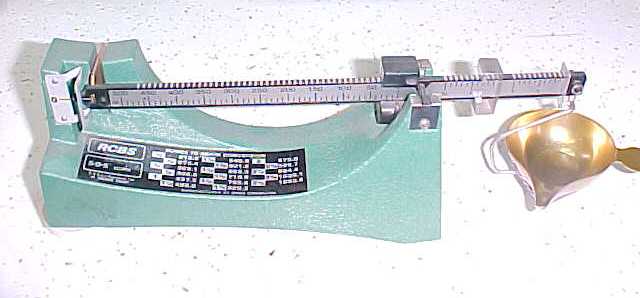

The desired powder charge weight is set by moving the sliding weights on the beam so they total the desired charge weight, and powder is then trickled into the scale pan until the scale is balanced. In order that the entire powder charge doesn't have to pass through the trickler, a small amount of powder can be added to the scale pan with a dipper, and the balance trickled.

The above photo shows the beam weights set for a weight of 46.0 grains The "tens" weight is set to 40, the "ones" weight is set to 6, and the "tenths" weight is set to 0, adding them up yields 46.0 grains. (Did I mention powder is sold by the pound but used by the grain? There are 7000 grains in a pound of powder)

Once the powder charge has been weighed, it is transferred to a case by dumping the scale pan into a case funnel then passing to the case. Note that I have the unfilled cases upside down in hopes of avoiding spillage of powder into a stray case in the event of a mistake.

Some Scale Prices for Comparison

These are wholesale prices effective 3-7-03

Lee Safety Scale - $17.95

RCBS Model 5-0-5 - $54.90

Hornady Scale - $37.70

This will take you to the Reloading Index