IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGEThis will take you to the Reloading Index

Steve's Rifle Cartridge Reloading

These are the techniques and equipment that

I use to produce reloaded cartridges for bolt and semi-automatic rifles. Other techniques and equipment may be: better/worse, cheaper/costlier, safer/more dangerous or whatever. Read this stuff and use it or not, at your own risk!Components

In addition to new or resized brass cases, you will need Bullets, Primers, and Powder to make a finished reload. The exact selection of each of these is made using loading books or charts, and some times by the amount of money in your wallet.

BULLETS

Bullets are sold in boxes of 100 (50 in the case of the larger sizes), or bulk in lots of 500 and up. The diameter and weight must be suitable for the caliber of the rifle. The caliber is sort of set by the diameter of the bore and that is not easily changed J. For any given caliber there exists a range of bullet weights that bullet manufacturers have found suitable for that specific caliber.

In addition to different weight bullets, different styles of bullets exist. Ý Ý Ý The two left-most bullets above are "boat-tail" style. Note the tapered rear end. These provide superior long-range performance. The one to the extreme left is a Hornady A-Max with a plastic nose and also is "moly-coated" (that explains its grey-black look). The two on the right are flat-based bullets, simpler to manufacture and having greater bearing surface against the interior of the barrel. Flat-based bullets are known for short-range accuracy. The one on the extreme right is a 30-caliber armor piercing US military bullet; the black tip is paint used for identification purposes. The two in the middle and the one on the right are cannelured or grooved. When used as designed, the extreme end of the case is crimped into this cannelure or groove, securing the bullet tightly in the case mouth.

Ý

Ý Ý These are the same bullets viewed from the rear. Most bullets are made from a brassy closed end tube (looks like a fired 22 shell without the rim or maybe a thimble) filled with a dense filler, commonly lead. Once the tube is filled, the whole thing is "swaged" in a mould using very high pressures. The three on the right are showing the exposed filler, the closed end of the brassy tube is at the front. The "match" bullet on the left had the closed end at the rear, and the open of the tube is at the front. The plastic "nose" closes the open end of the tube.

PRIMERS

Primers come in boxes of 1000 Ý Ý Ý and boxes of 100 and 5 boxes of 1000 in a case (5000). For rifle, the two major divisions are - Large Rifle - and - Small Rifle. This refers to the diameter of the primer and the primer pocket. Both large and small sizes come in Regular, Magnum and Match (Bench Rest) and at least one manufacture offers a Magnum Match Primer. The two orange and green styled boxes are Russian made primers, the rest are identified. CCI makes a Large and Small series of primers that are supposed to duplicate the current US military primers (not shown).

These Ý Ý Ý are boxes of 100 primers. The different packaging styles reflect the individual manufacturers' concerns about adjacent primer detonation. (If one goes off accidentally, will the whole box go off ?)

This is a "Large" Primer.

And a "Small" primer.

While these primers will fit pistol cases and vie-versa, it's a BAD IDEA to use pistol primers in a rifle. The pistol primers have thin skins, so to speak, and are liable to rupture a rifle pressures. The rifle primers, being of sturdier construction, may not "fire" with the weak strike provided buy a pistol hammer/pin.

POWDER

Powder is sold in one and two pound canisters and is referred to as "canister powder". The manufacturers attempt to maintain the same exact specifications over the years, so that a type of powder made ten years ago will act the same as that same type of powder made this year.

Another choice is bulk or surplus powder. This is commonly sold in eight-pound plastic jugs. THE CONSISTANCY OF THESE POWDERS IS NOT GUARANTEED! Some of this powder is obtained from US govt. stocks and some is commercial surplus and some is even surplus from foreign manufacturers. (Allen is my brother, he owns the marked jug, and because of lot-to-lot variations, picks an eight-pound jug and uses it for a year. Next year he will pick a new one and work up his loads for the year. But he's a real paranoid competitive shooter!)

Powder is selected by its "burning rate". Powders with a "fast" burning rate tend to be used in smaller cases with lighter bullets, while "slow" powders are used in large cases with heavy bullets. The slowest powders available are used in 50 cal. MG loads behind 900-grain bullets.

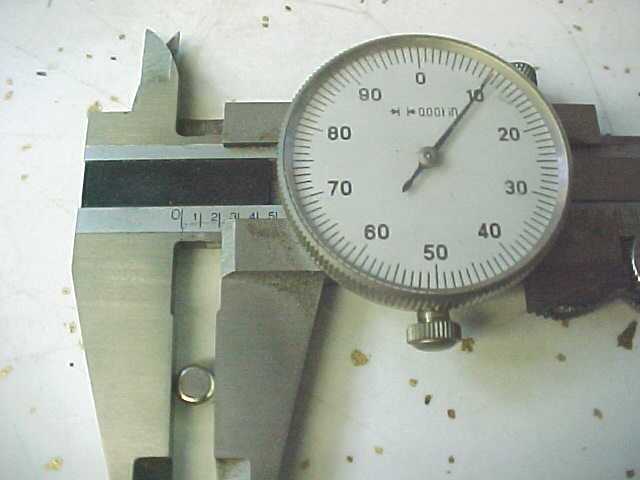

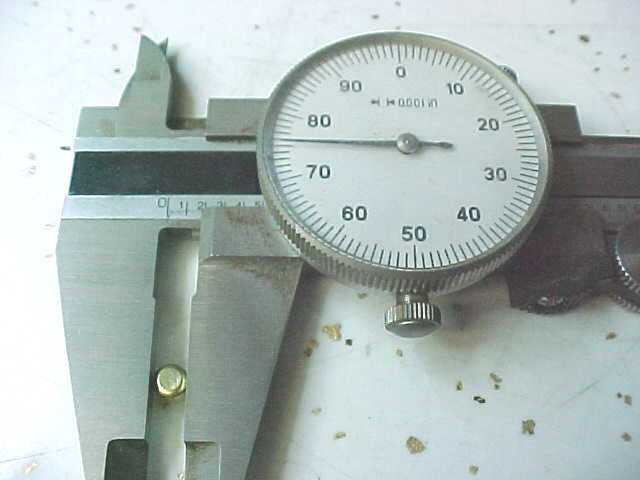

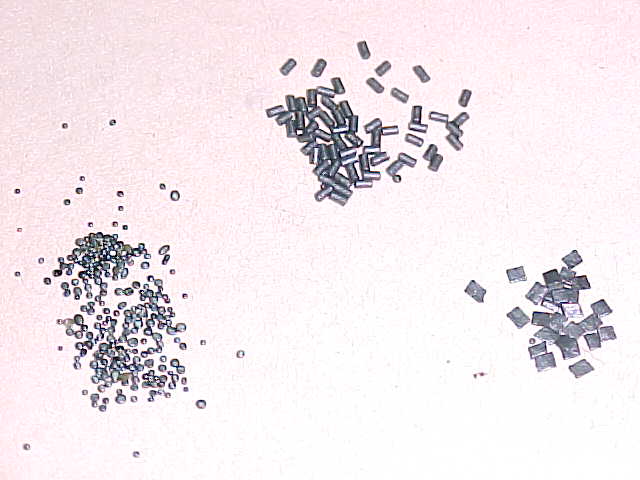

Powder is manufactured by various processes, resulting in various shaped powder grains. These are the three most common and are encountered in all of the different burning rates. The shape of the grains does not determine the rate, but if the grains are mangled, the rate may change. The powder on the left is "ball" powder; the grains are small round or oval balls that have been covered with graphite. (This is the powder that was "blamed" for the malfunctions/design deficiencies of the AR15/M16 during the Vietnam War. The real problem was the design and maintenance of the rifle! And it's the only powder I use in our AR clones.) The powder in the middle (top) is extruded. It looks like short pieces of thin pencil lead. The most common extruded powder is the "IMR" (Improved Military Rifle) line of powders. On the right is cut or sheet powder, manufactured in thin sheets and then cut into small squares or triangles.

Here is a link to a powder burn rate chart I stole from the web. I have saved it to my site as it has disappeared from the web.

And here is a chart of Loads per Pound of powder.

Powder should be stored in cool dark places like wine cellars or basements. When opened, a smell of acetone or toluene is good. If the powder smells bad, burns your nose, or is getting a reddish cast, it's time to spread it in the garden or lawn; it makes a good, but expensive fertilizer.

In general, the IMR series of powders are the most flexible, working well at light as well as heavy loads. The ball powders work best in near full-case loads, and sometimes require Magnum primers, even in non-Magnum cases. Some feel that using ball powder will give longer barrel life.

This will take you to the Reloading Index