Budget Action Vise (Wrench)

As I have said in the other

texts that compose my web site, I think Brownells makes and/or sells the best thought-out

gunsmithing items available. I believe that is

especially true of their action vise (wrench) system. The "system"

consists of a handle and various heads, the heads being selected for the action

at hand. The Brownells wrench for the Large Ring Mauser (handle and head), along with a Small Ring Head is

shown below. The Large Ring Mauser wrench (handle and

head) costs $83, with no discount allowed. The individual heads purchased individually

cost $33 each, so it would be fair to say the handle costs $50, even though you

will pay $62 if you buy it alone.

The bolts used by Brownells are 1/2 x 20 tpi

socket head cap screws, they take a 3/8 inch Allen wrench. (I think you get a

set of bolts with the purchase of a head but it has been too long to be sure J .)

If you could make the heads,

you could save $33 each.

My suggestion is that, if you

make your heads, you use dimensions such that you could later buy heads or

handles and everything you have made will interchange. After all, if you

change/rebarrel enough Turks, you'll be rich, and

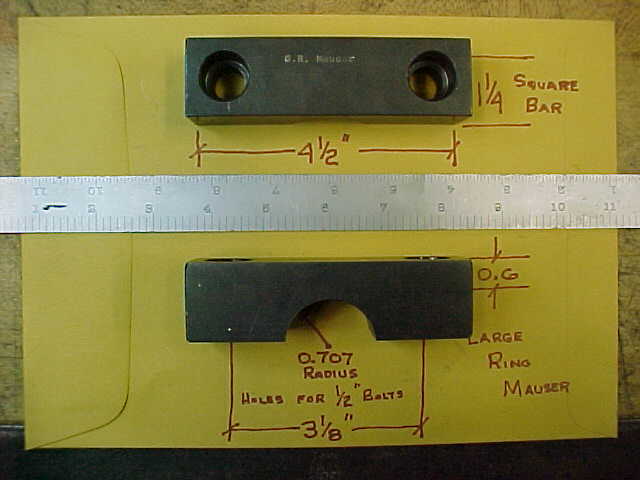

will be able to buy anything, right? Brownells heads

are made from 1 1/4 square bar 4 1/2 inches long. Centered on the bar are two

holes, 3 1/8 inch Center-to-Center for the 1/2 inch

bolts. Brownells' counterbores

the holes for the cap screw heads, a nice touch. Centered between these holes,

but on another face, is a partial semi-circle with a radius of 0.707 or better

0.710 inches, with the extra 0.003 inches allowing for an aluminum shim made

from a soda can. 0.600 inches of metal remains above the cutout.

If making a head is not an option,

because of insufficient machinery etc, then buy the Brownells head(s) and save $50 my making the

handle, thatís the easy part.

This shows the Brownells action wrench in action. If the action

was blued, an aluminum shim could be wrapped around the top half of the action.

But, take note of the cutout portion of the handle that allows for the recoil

lug. If not for this cutout, the wrench could be made form a solid bar, with

two holes, tapped or not, for the bolts.

This shows the

"economy" handle, just a piece of bedrail, with two holes and a

notch. This one is about 3 feet long with the action at the end. If your

bench/shop will stand the extra length, use a four foot

piece and but the action in the middle. Then two of you can use it, one on each

end.

At the end (of the bedrail or

light angle or maybe tubing?), or better, in the middle, drill two holes for

the 1/2 inch bolts. Drill them as near to the "other" leg of the

angle as possible (see below), while leaving room for the nuts-on the

underside. Then draw a line so that it just touches the edges of the bolt

holes, thatís the long black line seen above. Then cut, with a hacksaw, in two

places, from the edge of the angle to the line, the cuts being centered between

the holes and 1 1/4 inch apart. These are the short lines seen above. Then use

a chisel and notch the along the black line from cut-to-cut, grab the piece

between the lines with a Crescent wrench and wiggle to-and-fro until it breaks.

These two pics show the

underside of the homemade handle, and the pieces that comprise the wrench. You

don't have to use socket head screws, and buy nuts to match whatever bolts you

are using. Remember, I think the Brownells

wrench is great, but don't pass up the opportunity to save money and buy some

more Turks. A friend, Neil, gets nervous if I don't get a shipment every 2

weeks or so, says something about it being an addiction.