IF YOU REACHED THIS PAGE VIA A SEARCH ENGINE

THIS WILL TAKE YOU TO OUR HOME PAGEThis will take you to The index for this series.

A 6.5x55 Match Rifle

Page 3

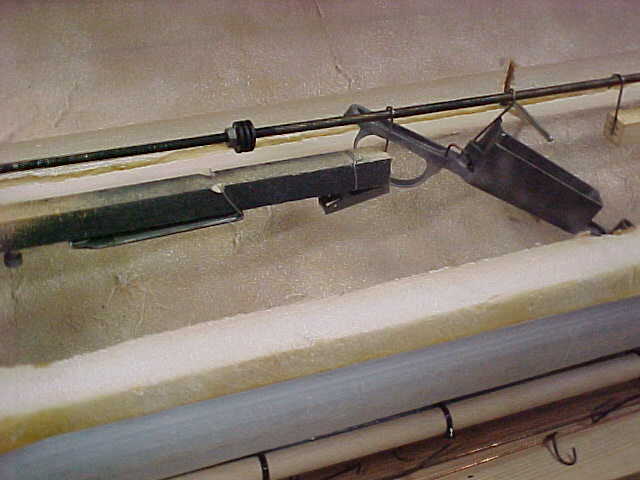

The small parts were fastened to short sticks. The ejector spring gets its own stick (in the rear), as it will be painted a different color.

My blast cabinet is a cheap Chinese plastic box that the previous owner fitted with a Shop Vac and light.

The media I used is Black Beauty (crushed slag from steel making), although common sand works well. Sand blast media seems to be a sort of locally defined stuff. I have found only one outlet in the area and he seems to supply everyone. The media comes in two styles, 1. Sand, graded and packaged locally, sold as fine, coarse and in-between, and 2. Commercial Media, bagged elsewhere and sold at a much higher price. When I change media, I'll go back to sand. If in doubt, ask for the sand used in autobody work, seems just right.

I drilled a hole in the side of the cabinet for the barrel. Note the cleaning patch and candy-apple stick in the end of the barrel.

Here are the parts after blasting. I'll leave them on the "sticks" and paint them. These were used "sticks", see how the sand blast removed the black paint around the small parts? Ý Ý Ý

Here are the parts in the oven, being pre-heated prior to painting. Ý Ý Ý

The rifle was coated with Brownells Baking Lacquer, Matte Black, except for the bolt stop spring, bolt stop screw and floor plate quick release plunger. These parts were painted with Brownells Matte Stainless Lacquer.

Looks Good! See that the trigger loop has been has been narrowed as well.